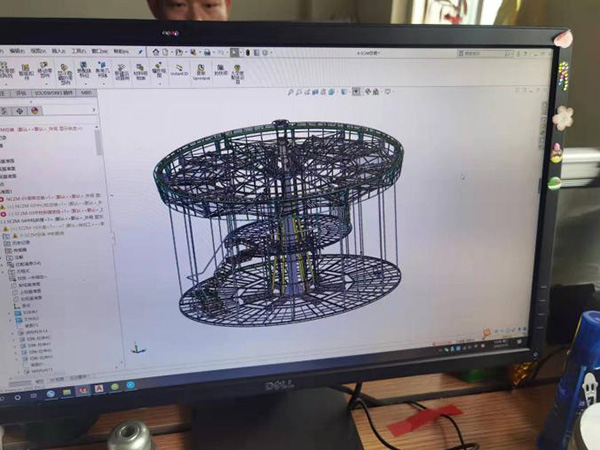

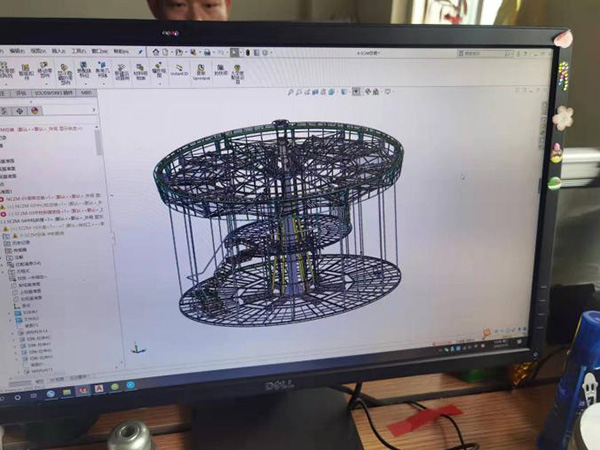

Design

Our professional designers use their skills and imagination to translate their ideas to reality . Ensuring all systems and each parts of our rides will be designed basic on the passenger safety.

Our professional designers use their skills and imagination to translate their ideas to reality . Ensuring all systems and each parts of our rides will be designed basic on the passenger safety.

We choose high-strength national standard steel, iron parts are fully welded, and we have our own independent cutting machine for small parts, so as to control the production of products more accurately and precisely. One machine will be including thousands of small parts, we insist on pay more attention on the details.

We have our own modeling room, and use thicker FRP materials that is more durable, which lays a solid foundation for the quality of the product. Make sure it can resist long-term exposure to the sun and rain without deformation.

Before the rides leaving our factory, each rides will be through the strict testing process, make sure it is achieve our products quality standard, then will be permit to loading to your park!

We insist on the process of spray paint for many times, anti-rust paint, primer, and craft paint. This makes the product less prone to rust and discoloration.

Keep the products beautiful and attractive all the time. Usually, we choose bright and suitable colors for the rides, to keep same attractive as the design. We are also welcome specialized colors as customer’s requirement.